Keep your RV in good shape. Photo courtesy of U.S. Air Force (Marcus Hill)

Why It’s Important To Check Your RV’s Frame

I was recently sitting around the campfire while camping with some friends, and as it typically does, the conversation turned to RVs.

One friend mentioned that he had studied RVs at length before he purchased one himself. He had looked at RVs built by the same manufacturer as my travel trailer and discounted that manufacturer, as he didn’t like the way the A-frames on their travel trailers were designed, especially like my A-frame designed for travel trailers with higher clearance.

Having been in the RV industry for most of my life, I somewhat disregarded his opinion, as I could count on one hand the number of A-frame failures I had encountered in over forty years.

However, as I was doing some other work on the front of my trailer, his words came back to me and I decided to take a closer look. Sure enough, there were stress cracks where the A-frame met the first crossmember on the door side. I found the same thing when I examined the opposite side.

Cracked frame

Luckily, I know how to weld and have a welder (and a long extension cord) at home and was able to repair the trailer the same day as we had a trip planned the next day.

As I pointed out a while back when my entry door lock failed, my wife and I log considerably more miles than the average RVer. In addition, we like to boondock, which puts us on rougher roads than most RVers are comfortable with, so the chances of this happening to your travel trailer is much less likely.

However, it emphasizes the fact in being diligent and checking your frame along with other items that we seldom check, but ought to, like lug nuts, spare tire pressure, water heater anode (out of sight, out of mind type things), etc.

This is not a one-size-fits-all solution type of repair. If you find signs of failure with your RV’s frame, I highly recommend you take it to a certified frame shop.

Keep track of your maintenance

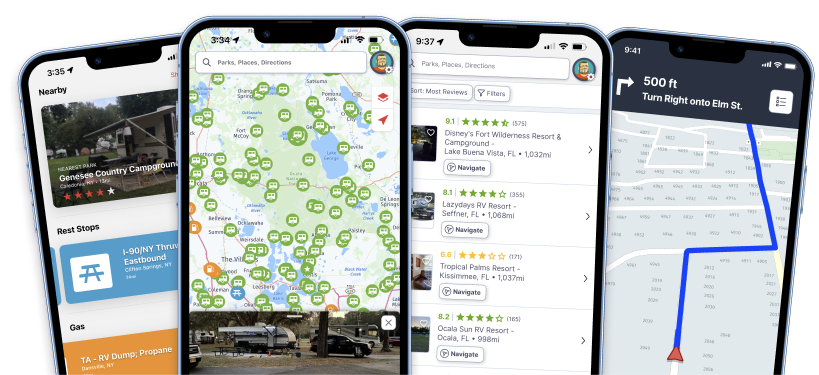

There is a lot to keep track of when it comes to RV maintenance, and it’s not easy keeping everything nicely organized and readily accessible. That’s where RV LIFE Maintenance comes in handy.

RV LIFE Maintenance makes it easier than ever to track your RV maintenance and fuel economy, organize documentation, and find out what needs to be done next. You can even receive email alerts for timely reminders when tasks will need to be done soon.

Whether you have a small trailer or large Class A motorhome, RV LIFE Maintenance can keep track of it all, along with up to two other vehicles, such as a tow car, motorcycle, or four-wheeler. Learn more on MaintainMyRV.com.

Nearly all small trailer frames are not designed for operations off paved highways. Additionally, they make no provision for internal corrosion maintenance. So they rust from the inside out within a few years. Flexing frames overstress the shell and nearly all other components which can destroy the entire unit. Any trailer intended for secondary road use or worse needs an upgraded frame designed to take constant pounding at real-world weights and corrosion proofing maintenance facilities built in.

I appreciate your comments. We are new to the RV world and haven’t purchased yet. Currently feels like we are in analysis paralysis. Researching and reading constantly. Trying to buy quality without emptying our savings, but keep changing our minds as to length, type, necessary amenities, etc.

I once owned a 28ft Weekender tt, after the 3rd time the frame broke I called the manufacturer personally and they told me it wasn’t meant to be used every WEEKEND.

This is precisely right. With the rarest of exceptions, factory small trailer manufacturers target volume and compete on price. The needs of individual owners are not considered. Typically, manufacturers don’t use their own product and leave product testing to the owners. So understandably, boondocker needs are not even comprehended by manufacturers, let alone provided for. Furthermore, John Doe owners almost universally buy on price rather than putting thought into their proposed application and buying accordingly. Even those who do consider their potential use,, the vast majority err on the modest side and quickly get involved in real-world applications that exceed what they originally intended. The majority of small trailers in service are being operated over their design weight and balance, resulting in HUGE owner liability. Caveat emptor.

This is the results of the word LITE in your purchase of a camper with that term in it’s description ! If you go for the camper you MUST yearly crawl under it and touch up the frame with Rustoleum of some rust proffer or it will be junk before the fiberglass makes it unusable.junk. If only somebody made their trailer out of heavy Aluminium instead of what we use to call sheetmetal but now call a Lite trailer. Yes this is a BIG deal.!

.

As the crack going along right at the original weld bead shows, the metal in the vicinity of weld points gets changed structurally a bit by the near intense heat while the rest of the area remains “cool”. That temperature extreme causes a weakness that leads to the cracking. Unless the designer of the RV chassis is totally inept, failure in the center of a span, or other undisturbed by welding areas is kind of rare.

LivinLite, RIP, has a recall going right now for cracked frames. They switched design on the newer ones- and now they are cracking. Apparently the company never had an analysis done by a mechanical engineer before putting them into production.

The parent company, Thor, (I spit when I say that) is picking up the charges.

Journeyman welder for 34 years. If you check out the quality of the welds on all trailer frames it will make you cringe. Unqualified people doing high speed production welding with no quality control or adequate weld supervisors in the manufacturing facility. I go over each trailer we purchase, grind out bad welds and re-weld those joints. I’m surprised that more of these A-frames don’t fail.

Always disconnect the battery And shore power before any welding on the RV.